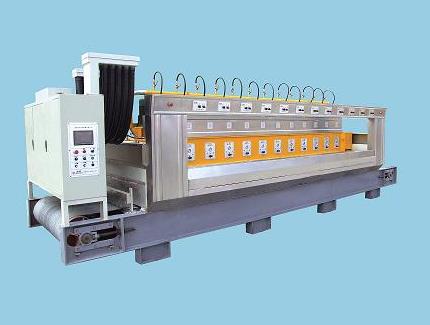

granite Slab polishing machine

- Advantages:

- granite slab polishing machine has 9, 12, 16heads,all sorts of specifications, is a fully automatic continuous polishing machine!

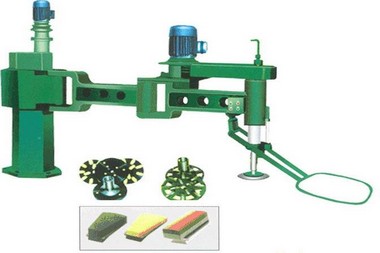

- Grinding Heads:

- 12~20

- Applied material:

- Artificial quartz slab, artificial marble slab and more grinding stone slabs!

Related Products :

Product Photo:

Products quality upgrade,give you more profits!

granite Slab polishing machine effectively solve the Surface rough, uneven thickness, luminosity not high three question,greatly improve the products grade,give you more profits!

24 years of development, we are trusted by many users around in the world.come on! we bring you see our case!

granite Slab polishing machine we manufacturing since 1992 year, in the past 24 years, our professional by countless stone processing factory choice and accepted!

Dear!!you have any further information needed, please send us an inquiry with your requirement.

Product Description:

granite slab polishing machine is the most advanced products of stone industry upgrading. all the electrical parts adopt famous brand, the PLC is Siemens and other electrical parts mainly are Schneider, so these can ensure granite polishing machine stability and long-term working.

utand granite slab polishing machine use the best quality belt of famous brand, promise the thickness of the slab. the out airbag for long life using, lower hazard rate, lower maintenance cost and with lower power (7.5kw single head),cost is only 0.5USD per square meter, Capacity is 38 square meter per hour. The brightness for G3786 can catch up 85 degree.

FAQ:

Q:How about utand granite Slab polishing machine After-sale service?

A:Utand Stone Machinery Standard delivery time for Machine is in 25 days,we provide guarantee spare parts ,installation drawing&operation manual,Training and all-around technical guidance for operation,commission and maintenance .If need our engineer to help install oversea,we act within 48working hrs.

Q:How many process of stone slab grinding and Polishing?

A:1)coarse grinding: required high grinding efficiency, grinding of coarse grain and grinded surface is rough, clear main products in before leave some traces saw blade and the product flatness, molding grinding in place;

2)half fine grinding: clear the coarse grinding trace, product processing and with smooth surface;

3)fine grinding: fine grinding after product particle, color and pattern has been clearly shown, fine and smooth surface, began to have a faint gloss;

4)fine grinding: after processed products without trace to the eyes. Surface more smooth, gloss about 40~50 degrees;

5)polishing: this step is the most the place of key light, generally need to use (0.3 um) alumina mirror polishing powder (vitamin k - L30F) for processing, processing of stone material surface bright as a mirror, have certain mirror gloss (above 85 degrees).

Q:How about the quality granite Slab polishing machine?

A: We are a manufacturer having over 24 years’ experience in stone processing machinery.our products are strictly made by adopting advanced technology both at home and abroad.Every aspect of our products is under strict quality control and we take a test on each equipment before delivery.

granite Slab polishing machine by integrated & strict quality control in every aspect!

Authoritative certificates: BV, CE, GOST, and ISO9001:2008

Remarks: The price will depend on different models.

Technical Parameters:

Processing width | max 900mm |

Processing thickness | Max 50mm |

Grinding Heads | 12~20 |

Capacity | 150-300 square meter per 8hours |

Grinding head power | 12~20x7.5kw |

Belt move power | 1.5kw |

Bridge move power | 4kw |

Belt move speed | 600-2200mm/min |

Pressure | 0.6-0.8Mpa |

Cooling water pressure | min 0.15Mpa |

Consumption water for single grinding | 25L/min

|

Diameter of the granite polishing disk | 200mm |

Machine size | 7000*2200*2100mm |

why chose us?

The past 24 years, we have succeeded to provide one-stop service for more than 500 stone processing plants in more than 20 countries around the world .

We provide the most professional stone processing technology and stone machinery!

We free to answer your problems of stone processing plants!

We free to answer your problems of stone processing plants! We provide you the most professional stone processing machinery!

We provide you the most professional stone processing machinery! We provide you permanent services with stone processing plants!

We provide you permanent services with stone processing plants!

Hi, we intend to sell this website, if you are interested, please contact us:

Email:529733977@qq.com

Address:Huanan industrial park,Foshan City,Guangdong Province.

Contact Us