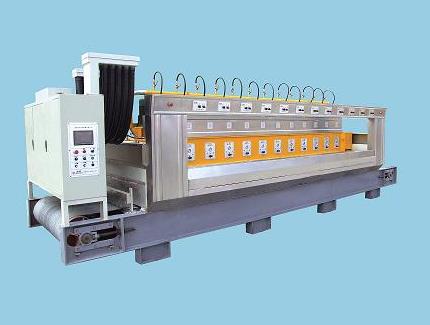

stone polishing machine nz

2018-06-04 20:34:38 By:Utand Stone Machinery (1882)

stone polishing machine nz

Speaking of stone polishing machine nz, I believe you are not sure what it is, for this equipment will have a strange feeling. So, what is the stone polishing machine nz in the end? As a matter of fact, stone polishing machine nz is a kind of equipment which can run quickly with mechanical equipment and "dry polishing, wet polishing" to achieve polishing effect. Then, let's introduce the working principle of the stone polishing machine nz and the knowledge content of the influencing factors by UTAND STONE MACHINERY.

Physical and chemical principle: the process of polishing is 2, that is "dry polishing and wet polishing". The polished millstone has physical and chemical effects between "dry and wet" between "dry and wet". Dry polishing is the evaporation of water on the surface temperature of the stone, resulting in the increase of the concentration of polished grindstone, so as to achieve the strengthening effect, the glossiness of the product begins to reach the beginning. To the ideal requirement, the gloss is above 85 degree or higher.

In the current market situation, user experience accounts for about 80% of customer satisfaction, largely determining whether the stone polishing machine nz will be purchased.

Particle grinding: when the abrasive particles are grinded from coarse to fine grinding and polished, the trace of grinding on the surface of the stone is from coarse to fine to no naked eye. The surface is smooth, smooth and delicate. When the depth is 110 microns, the surface has a mirror gloss, bright color and bright color.

An introduction to the factors affecting the work of stone polishing machine nz:

The type of polishing agent: Although polishing agent is a special polishing material, the difference between it and grinding material is mainly in the processing mechanism. In principle, some low hardness micropowder materials can also be used as polishing agents. But usually the high hardness polishing agent is better than the low hardness and has wide application scope.

Polishing fluid: water is a common polishing liquid. It can not only play the role of grinding cooling, but also be used as a medium for physical and chemical action in polishing process. If the polishing of stones is mainly based on mechanical grinding, such as diamond micro powder, polishing oil generally uses organic liquid like oil, such as sewing machine oil. Its cooling, lubricating and dispersing functions are excellent. Diamond grinding paste has both water quality and oil quality, and coloring agent can also be added.

Discs: the smooth surface of the stone light panel is a form of expression of the stone plane grinding, and the hard disk made of metal materials is used as a discs. The polished surface of the floppy disk is easy to yield to a concave surface when the stone is pressed, and is suitable for the arc surface polishing. The hard disk has good abrasion resistance and good absorbability, and has a certain elasticity.

The above is the related content of the working principle and influence of the stone polishing machine nz introduced by UTAND stone machinery. Although stone polishing machine nz is not often seen in our life, but consumers can understand it well. Therefore, we hope that after introducing the introduction of UTAND stone machinery, consumers will have a more comprehensive understanding of the stone polishing machine nz.

stone polishing machine nz useful

stone polishing machine nz is mainly used for polishing of stainless steel plate, polishing and polishing of marble and granite. It can also be used in gravestone, stone glass, artificial stone, cement products and other kinds of plane polishing and grinding. Ordinary grinding stones can be used and diamond grinding plates or resin grindstones can be used to achieve rough finishing. The products are highly polished and achieve mirror effect.

stone polishing machine nz has the characteristics of high automation, simple and convenient operation, advanced performance, good surface evenness, high brightness, fast processing efficiency and stable quality of the product after processing.

Polishing of the product: the polished millstone is placed on the processed product. The polishing effect is achieved by the quick operation of mechanical equipment and "dry polishing and wet polishing". The surface of the product will have a very strong reflection light, which is usually described as gloss.

The process parameters include the concentration and supply of polishes, the pressure and line speed during polishing. The polishing speed increases with the increase of the concentration of the polishing agent before the concentration is smaller than a certain concentration. After the concentration is maximum, the polishing speed will decrease if the concentration is increased. Similarly, when the supply of polishing agent is at a certain value, the polishing speed is the largest. If the supply continues to increase, the polishing speed will decrease. Properly increasing the pressure during polishing can increase the polishing speed, but the pressure is too high and the grinding effect is strengthened, which is not conducive to the formation of the gloss surface. The polishing speed depends on the rotational speed of the discs, but the line speed is too large. The polishing agent will be thrown away, resulting in waste.

automatic Stone Polishing Machine

Theoretically, different minerals should use different polishes. Polishing is a fine processing technology for stone, and it is called surface polishing technology. There are many factors affecting the polishing of stone. There are problems in the process conditions and parameters in the process of polishing. There are also kinds of polishing agents and auxiliary materials and the problems of discs and discs. It is also related to the mineral composition and quality of stone.

-

Related News:

- artificial quartz stone plant

- stone calibration machine for sale

- 12 heads stone polishing machine

- quartz stone press machine

- artificial stone machinery suppliers

- wet stone polishing machine

- artificial quartz stone production line of common problems and solutions

- artificial quartz stone machinery factory advantage than traders

Hi, we intend to sell this website, if you are interested, please contact us:

Email:529733977@qq.com

Address:Huanan industrial park,Foshan City,Guangdong Province.

Contact Us