artificial quartz slab production line process introduce

2016-11-28 09:52:10 By:Utand Stone Machinery (3213)

artificial quartz slab as a kind of new building decoration materials, the biggest advantage of view from the vision, colorful and lively, species diversity, can produce different color according to the needs of users; High brightness, reflective effect is good, the surface after anti-pollution treatment,natural and comfortable, although look shiny but prevent slippery effect is good; If you use longer, quartz surface was polished renovation at the scene, convenient and simple.How the machining process of artificial quartz slab production line is? Utand Stone Machinery introduce for you:

artificial quartz slab production line process description

First of all, is the preparation of raw materials, configuration and decorating of raw materials for artificial quartz slab

Choice raw materials:

filter on raw materials and auxiliary materials such as quartz, resin, glass , filter out the impurity in the raw material, scrap iron, ensure the clean and size of raw materials for (if too many impurities, will seriously affect the quality of the quartz plate)

stir ingredients:

after of material choice, the completion of the appropriate proportion of raw materials in accordance with the formula into the mixing system. In artificial stone mixer, raw material will eliminate material colour difference, and fully stirring, the dye, additives, resins and other raw materials even mixing into quartz plate of raw materials.

decorate of hybrid material:

hybrid materials will be sent to cloth car by transfer belt, the cloth car cloth material uniform cloth such as mold frame.

Vacuum high-pressure forming step completed at the same time

artificial quartz stone slab machine

Utand artificial quartz stone machine effectively shorten the vacuum time (30 s or so can reach 0.1 MPa), greatly improve production efficiency.a groups of vibration motor adopts synchronous vibration,the vibration of 80t powerful,the finished product the thickness of the plate can be changed from 10-50 mm

High temperature curing finalize the design

After completion of suppression, blank artificial quartz slab into the high temperature curing furnace heating (85-110),then artificial quartz slab production line complete

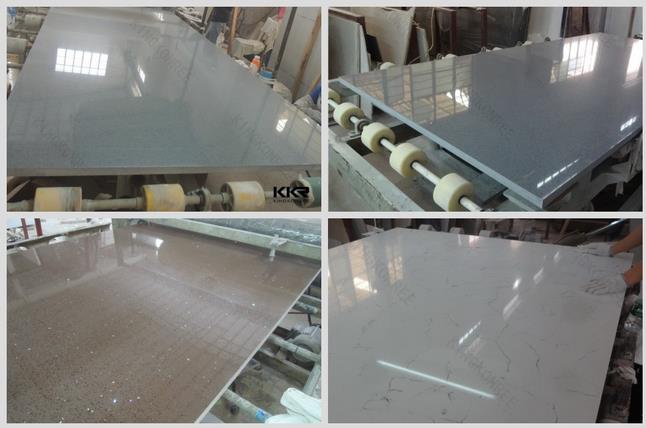

artificial quartz slab production line customer case

-

Related News:

- quartz stone slab calibration machine

- stone polishing machine suppliers

- Artificial quartz plate turnover machine

- quartz stone pressing line machinery

- single head stone polishing machine

- artificial quartz pressing machine

- What are the basic classification of artificial stone?

- artificial stone production line machine price

Hi, we intend to sell this website, if you are interested, please contact us:

Email:529733977@qq.com

Address:Huanan industrial park,Foshan City,Guangdong Province.

Contact Us