how to make solid surface

- Advantage:

- How to make solid surface is the first question that solid surface manufacturer should solve, utand tells you how to make solid surface with 15 years of solid surface production line design experience.

- Description:

- Manufacture solid surface includes MMA resin making system, mixing system ,casting system ,transport system ,and calibrating and polishing system.

- Voltage:

- 220V or 380V

Email : info@utand.com

What is solid surface stone?

If we want to learn how to make solid surface, we must first understand what is solid surface stone?

solid surface is a kind of polymer composite, which is made of methyl methacrylate (MMA,), unsaturated polyester resin ((UPR)) and other organic polymer materials, with natural mineral powder, particles as fillers, pigments and other auxiliaries, vacuum casting or molding.

solid surface stone appearance surface is smooth, color beautiful, has certain transparency; has enough strength, stiffness, hardness, impact resistance, good scratch resistance; has resistance to climate aging, deformation and sudden cooling and heat; from bottom to surface solid, no pores, no dirt, easy to clean, long and often new.

solid surface slabs seamless splicing, smooth and smooth surface; heat resistance, cold resistance, corrosion resistance; Can be cut and heated bending, shaping a variety of different shapes.

solid surface stone retains the nobility and elegance of natural stone, overcomes the defects of capillary, crack, color difference, radioactivity and so on, and quickly becomes an international popular high-grade environmental protection decoration material.

how to make solid surface video

This is our india customer's solid surface polishing line working video, is showed the detailed process of making solid surface. Welcome to our factory,We'll show you more details for how to make solid surface.

make solid surface countertop technical

make solid surface countertop technical control are as follows:

making solid surface countertop most important and basic molding process is the curing of resin, and the process of resin changing from liquid to solid can be completed without pressure and room temperature.

From the chemical principle, it is the process from linear structure to body structure. After curing the resin, the liquid resin becomes a solid body structure, insoluble and insoluble crosslinked polymer, and has a certain strength, hardness and toughness.

how to make solid surface video

process of how to make solid surface

process of how to make solid surface is more complex, and we can produce the solid surface stone with high quality as long as we have a good grasp of every process.

solid surface of ingredient process

UTAND make solid surface process is necessary to pay attention to whether the addition of various raw materials is accurate in the preparation process. Because of the addition of the color paste, the base color, the particle, the filler and the top coat of the board can affect the high and low of the key process parameter viscosity, and the color is particularly important.

solid surface manufacturing process

otherwise the requirement of the customer cannot be met, and the application value is lost. The added filler is usually aluminum hydroxide, which is mixed with the UP resin, and the prepared table has an agate-like texture, and the color of the finished product is bright and is favored by the consumer.

solid surface Defoaming process

Because a large amount of gas is dissolved in the mixing process, if the bubbles inside the product cannot be excluded, the quality of the product will be affected, so the defoaming process is very important.

The defoaming is divided into two steps: primary defoaming and secondary defoaming. The first is a single defoaming, the concrete implementation method is to control the vacuum degree of 0.9~1 MPa in the vacuum mixing tank, in which the tiny bubbles are difficult to drain.

In this how to make solid surface process, the viscosity of the system will be increased by stirring time, reaction time, and the level of viscosity will affect the quality of the plate. Viscosity too low will make particles precipitate, viscosity too high will make the bubble unclean so that the raw material after polymerization to produce a large number of pores.

how to make artificial quartz stone

curing process for making solid surface

make solid surface of curing process is carried out in the oven. It is the key to control the temperature of the oven, and the ambient temperature is also an important factor affecting the manufacture of artificial stone plate.

Therefore, there is a certain difference between the oven setting temperature in winter and summer. In winter, the ambient temperature is lower than the polymerization time, the longer the liquid material viscosity is, so the corresponding increase of oven temperature can shorten the polymerization time (about 40 ℃).

In summer, the temperature and oven temperature increase faster, so it is necessary to strictly control the indoor temperature and oven temperature to prevent the quality problems of the plate. The temperature of the plate from the oven can not reach the highest heating temperature, otherwise the plate will appear bow, crack, tortoise grain and other quality problems.

The time of plate polymerization should also be strictly controlled, which will make the plate have "watermark" prematurely. When the plate is pressed with pressed plate glass, because the plate is not completely polymerized, in the later stage of polymerization, it is necessary to overcome the pressure of glass and overcome its own internal stress, there will be fine cracks.

demoulding process

The demoulding process is the process of removing the plate from the oven and removing it from the mold. When leaving the die, we should pay attention to observe whether the hardness of the plate can reach the degree that it can be separated from the die, leaving the die too early will damage the die to reduce the life of the die (made of fiberglass);solid surface plate is too party to cause the plate to bow up, so it is necessary to apply a certain external force to force it to shrink, and the plate should be pressed up with toughened glass after the plate is taken out, so as to maintain the smoothness of the plate to a certain extent.

In conclusion, how to make solid surface of UTAND is not a simple technique, but it involves many comprehensive knowledge and high technical content, and must have rich professional knowledge and practical experience, well-known curing mechanism, material performance and process control to make the update, Better solid surface stone.

solid surface making process

Times: 2018-09-07 19:21:49 Views:3208solid surface making process is the production of various solid surface process, is through a variety of solid surface machinery reasonable process design, production of a specific specification of solid surface process.

artificial solid surface production plant

Times: 2018-10-13 08:42:37 Views:2995Now the artificial solid surface slab are becoming more and more popular, so there are many artificial solid surface production plant. How to choose a good artificial solid surface production plant? We need to consider it from all aspects.

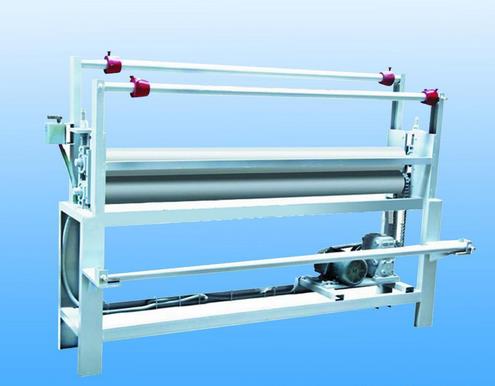

solid surface making machine

Times: 2018-12-26 08:19:54 Views:2552solid surface making machine have many kinds, such as polishing machine, turning machine, waxing machine, manipulator, so many solid surface making machine cooperate with each other to form a solid surface processing production line

production process of solid surface stone

Times: 2019-03-27 15:12:43 Views:2865Production Process of Solid Surface Stone directly affects the quality of solid surface slab, then what are the main influence factor of the Production Process of Solid Surface Stone?

acrylic solid surface manufacturing process

Times: 2019-04-30 08:10:17 Views:3451acrylic solid surface manufacturing process includes the following steps: mixing resin, filler, color paste, accelerator, additive and initiator in proportion, adding broken or short glass fiber into the mixture,

solid surface production line manufacturer

Times: 2019-05-18 07:53:47 Views:2405solid surface production line manufacturer can provide machines to produce solid surface stone. There are many solid solid surface production line manufacturer in China.

solid surface basin making

Times: 2019-05-30 07:32:21 Views:2574solid surface basin making is made from MMA, UPR and other organic macromolecule materials using artificial solid surface production line.

solid surface equipment manufacturer

Times: 2019-06-05 08:46:19 Views:2511solid surface equipment manufacturer the level of technology is different.UTAND stone machinery is a solid surface equipment manufacturer. At present, our company mainly produces two series of solid surface equipment,

how to make solid surface news:

Hi, we intend to sell this website, if you are interested, please contact us:

Email:529733977@qq.com

Address:Huanan industrial park,Foshan City,Guangdong Province.

Contact Us